hardness tester for steel|portable hardness tester for steel : distribution The DuraVision universal hardness testers for standard load ranges of 0.3-250 kgf or 3-3,000 kgf can be used for Vickers, Knoop, Brinell, and Rockwell tests, as well as for carbon and plastics testing.All methods are covered by the ISO . 18 de set. de 2023 · Catarina Paolino nude Onlyfans 18 de setembro de 2023, 19:22 75.9k Views 1 Comment Vazou nudes vídeo da Catarina Paolino no onlyfans, essa gostosa sedutora troca de blusinhas arias vezes marcando o biquinho do peito, famosa no tik tok e influencer acabou de entrar pro onlyfans, essa ruiva safadinha fica provocando em frente .

{plog:ftitle_list}

HBB Hostel - Vila Madalena se nachází v São Paulu, nedalek.

Test hardness right on your production floor. Unlike benchtop testers, these portable ones don’t require you to move large or hard-to-access parts. They use an indenter to measure the hardness of aluminum, brass, and steel. These testers can be used at any angle without affecting accuracy.Test hardness right on your production floor. Unlike benchtop testers, these .

Determine the hardness of very hard steel. To use, slide a test bar into the tester, . Starrett Hardness Testers are precision instruments used to determine the hardness of a material. With a range of models available, including Rockwell, Brinell, and .The DuraVision universal hardness testers for standard load ranges of 0.3-250 kgf or 3-3,000 kgf can be used for Vickers, Knoop, Brinell, and Rockwell tests, as well as for carbon and plastics testing.All methods are covered by the ISO .

Saladulce Mohs Hardness Test Kit Mohs Hardness Picks 5 Pack Mohs Hardness Tester Industrial Mineral Identification Kit Gem Jade Jewelry 5-9 Scratch Tester 3.8 out of 5 stars 52 2 offers from 499 $ 104 99A complete range of hardness testers and hardness testing machines for Brinell, Rockwell, Knoop and Vickers hardness testing, as well as consumables and accessories – all designed to improve the accuracy and efficiency of your materialographic . Related reading: Metal Hardness Comparison Chart: HV, HB, HRC Commonly Used Hardness Brinell Hardness. The Brinell hardness test uses a ball made of hardened steel or a hard alloy with a diameter of D as the indenter.. A specified test force F is applied to the surface of the material being tested, and after a designated hold time, the test force is .Another tool used to make these tests is the pocket hardness tester. This tool consists of a scale arm with graduated markings attached to a four-wheeled carriage. A scratch tool with a sharp rim is mounted at a predetermined angle to the testing surface. In order to use it a weight of known mass is added to the scale arm at one of the .

Hardness testing can be applied to various types of materials, some of which are listed below: Metals and alloys. Ceramics. Elastomers. Polymers and plastics. Films. Rocks and minerals. Importance of Hardness Testing. Hardness testing is important for a number of different reasons. The hardness of a material can be a critical parameter in its .Hardness testing is often required on the shop floor, sometimes with large parts, and other requirements that prevent using a traditional bench hardness tester. These portable testers deliver on that need. Shop Portable Hardness Testers. Portable Hardness Testers deliver the ability to test material hardness without the need of moving it to a .

PTC® Rockwell Equivalent Steel Hardness Testers and Brinell Scopes. N.I.S.T. (National Institute of Standards and Technology) Traceable Calibration Available . Products [3] Quick View. Steel Hardness Tester PTC® #316 316 ,295.00. In Stock. Choose Options. Quick View. Steel Test Blocks 316.Test-Block- 0.00.The typical test uses a 10 mm (0.39 in) diameter steel ball as an indenter with a 3,000 kgf (29.42 kN; 6,614 lbf) force.For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is substituted for the steel ball. The indentation .

Examples of indent spacing in the Vickers hardness test for metallic materials . For steel, copper, and copper alloys: Spacing between indents must be at least three diagonal widths ; For lead, zinc, aluminum, and tin: Spacing between indents must be at least six diagonal widths . For the Knoop hardness test, the two halves of the long .The Jominy test (End Quench Test) is a standardized test procedure used to determine the hardenability of steel, and it can be performed using any Vickers micro hardness tester. The procedure is described in the following standards: ASTM A255 / ISO 642 / DIN 50191 / BS 4437

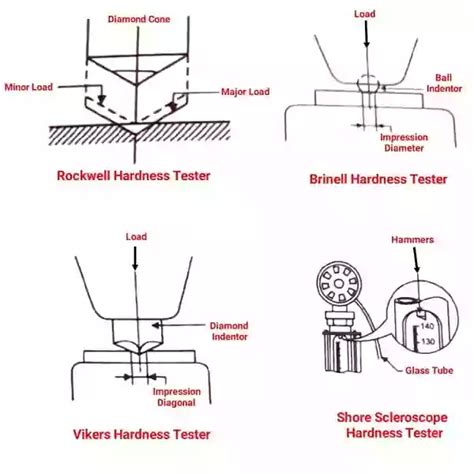

Brinell Hardness Test. The Brinell hardness test entails measuring the diameter of indentation caused by a constant concentrated force applied by a steel or carbide spherical indenter on a test specimen. The steel ball indenter is first placed in contact with the material before a constant force is applied and maintained for a 10 to 15 second duration, known as the .The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials .A Rockwell hardness tester is designed to test the hardness of materials using the differential depth method. A typical Rockwell hardness testing machine consists of a load application feature, an indenter, a test anvil and a .

universal hardness testing machine

A test takes a mere 2 seconds and, using the standard probe D, leaves an indentation of just ~0.5 mm in diameter on steel or steel casting with a Leeb hardness of 600 HLD. By comparison, a Brinell indentation on the same material is ~3 mm (hardness value ~400 HBW 10/3000), with a standard-compliant measuring time of ~15 seconds plus the time . Hardness testing is a vital process in many industries. Our guide explains everything you need to know about this crucial technique. . Indenter: 120 diamond cone or hardened steel ball. Rockwell hardness definition: .

vortec 454 compression test

Buehler offers complete hardness testing solutions with hardness testers, hardness test blocks, and Buehler designed hardness testing software. Skip to content +1 847-295-6500 . laser for precise targeting, and ring light for accurate Brinell measurements. The steel casting ensures durability, reducing service costs and increasing up-time in . Portable Leeb Hardness Tester Kit with Test Block,Hardness Testing Equipment,Rockwell Metal Hardness Meter Durometer for Steel,Aluminum Alloy,Copper,7-in-1 HL, HV, HB, HRC, HRB, HRA, HS 4.7 out of 5 stars 7

Hardness testing is the procedure of testing the hardness characteristic of a material so properties such as strength, wear resistance, and ductility can be determined! Product Category; Calibration; Delivery & Returns; . 316L stainless steel: 140HV30; 347L stainless steel: 180HV30; Carbon steel: 55–120HV5; Iron: 30–80HV5; Martensite: 1000HV; Steel - Testing, Properties, Manufacturing: The testing of steel’s properties often begins with checking hardness. This is measured by pressing a diamond pyramid or a hard steel ball into the steel at a specific load. The Vickers Diamond Pyramid Hardness tester, which measures the DPH mentioned above, uses an indenter with an included angle of 136° . Where: R eH is the upper yield strength; R m is the tensile strength; H RB is Rockwell hardness.. 2.1.2 Relative deviation analysis of conversion results. Based on the fitted quadratic regression model, the relative deviations between the converted values of upper yield strength and tensile strength and the results from the tensile test were calculated and .Model No. PHT-1900 Features. State of the art, digital portable hardness tester is designed to test the hardness of large hard metal parts. Clean crisp display shows the incredible functions that can only be found on this new portable hardness tester such as auto-probe detection, auto direction detector, single and multi-point calibration make the new 1900 the most versatile .

A Vickers hardness tester. The Vickers hardness test was developed in 1921 by Robert L. Smith and George E. Sandland at Vickers Ltd as an alternative to the Brinell method to measure the hardness of materials. [1] The Vickers test is often easier to use than other hardness tests since the required calculations are independent of the size of the indenter, and the indenter .Hardness testing is essential in evaluating a material's properties, such as strength, ductility and wear resistance. The REED R9030 measures a wide range of materials including: cast steel, alloy steel, stainless steel, aluminum, bronze, copper and cast irons.TH-170 is a portable leeb type metal hardness tester made by TIME. It is used to test the hardness of steel and other metals in a non destructive manner. Verification Certificate now available on selected items. . Metals that can be tested include Steel (CWT, cast etc), Stainless Steel, Aluminium, Cast Iron, Copper and more. .Portable hardness tester factory calibrated for steel, operating on the Ultrasonic Contact Impedance method with Vickers being the native unit of measure and conversions to other units according to ASTM E140 standards. Kits include a QH5U hardness tester with chosen probe, HV reference test block, coupling paste, user manual, USB stick with .

types of hardness testing methods

portable hardness testers for metal

Coroas Caseiras o seu portal de putaria diária. Aqui você vai encontrar Fotos Amadoras de Coroas, sexo com coroas bucetudas e muito mais.

hardness tester for steel|portable hardness tester for steel